Master Guide to Neon Signs

Here at Carousel Lights we’ve got an awful lot of experience in making both real neon signs and LED neon signs and we get asked many questions about both types of signs. We don’t have a bias towards one or the other so we thought this master guide would be helpful for anyone considering commissioning their own decorative light. If you think anything’s missing then let us know and we’ll add to it. The first section of this guide relates to real neon and the second half relates to LED ‘neon’ signs. We hope it helps!

What is neon?

‘Neon’ is a generic term used in the signage industry to describe neon lights but neon itself is actually the chemical element Ne. It’s one of two noble gases, the other being Argon (Ar), used to create the full range of colours in neon lights. When placed in an electrical field, Neon glows Red and Argon glows a Blue/Lilac colour. Being inert gases, both gases are colourless, odourless and completely safe and stable. For that reason, they’ve been used in domestic applications such as lighting for a long time. They used to be used purely as a source of illumination, much like striplights, where the tubes aren’t actually visible but are instead used to light up something else such as the inside of a built-up letter. More recently, the appeal of neon has increased to the extent where there’s high demand to see the tubes themselves, and the likes of Tracey Emin creating ‘Neon Art‘ has led to a huge demand in this type of lighting.

How are neon signs made?

12mm Turquoise and Hot Pink 1.5m long neon tubes

We start with what we refer to as neon tubes. This is the raw product that is delivered from the glass supplier and comes in various diameters and colours. The type of glass we use to make a sign is dictated by the final colour effect we want to achieve and the glass diameter is dictated by the design we’re creating, particularly the radius of the tightest neon bends. The most common diameters of neon glass we use are 10mm and 12mm.

A 100% mirror-image pattern of the design is printed out and laid on the workbench. The glass tubes are heated over a burner to the extent that the glass can be bent by hand and the tubes are then hand-formed to follow the design. Each neon tube is 1500mm long but they can be lengthened or shortened as required.

We often need to use more than one piece of glass to create a neon light which will then be joined together at the end with cable. We refer to these as ‘sections’ so you may notice that your neon sign is made from say 3 or 4 sections of glass.

Once all the glass has been bent to the shape of your design, electrodes are placed on the two ends of each section of glass and a vacuum pump is used to remove air from the glass tubes. A high electrical charge is then  applied to the tubes which removes any impurities following which Argon or Neon is connected to each tube which is sucked into the tube as the vacuum is released. The electrode is sealed and that section of glass is complete.

applied to the tubes which removes any impurities following which Argon or Neon is connected to each tube which is sucked into the tube as the vacuum is released. The electrode is sealed and that section of glass is complete.

Before the final stage of assembly we paint the glass with blackout paint as required. With designs, especially lettering and text, being made from a single piece of glass, we black out areas of glass that connect two letters together so it doesn’t illuminate. We will also paint the electrodes if we don’t want them to be part of the visible design.

Mounting template being marked up for location of tube supports

The final stage is the exciting part of assembly where the whole sign takes shape! A 100% scale template is placed onto the surface where the neon will be mounted, often acrylic, and the glass sections are placed on top. We mark the areas where the supports will be located – we typically use 3-4 supports per section. We then remove the template and drill the supports to the surface. The neon tubes are then clipped to the neon supports and it’s now starting to look like the sign that you had in mind! The electrodes of two sections of glass (the start and end, let’s call them) are connected to a transformer and each other section of glass is connected together using specialist neon HT cable. The type of transformer we use depends on several factors which are outlined below.

The transformer is then connected to the mains power supply and hey presto, we’ve brought a stunning 2D concept design to life as a living working 3D neon light!

Argon gas glowing blue inside a Hot Pink neon tube

How are different neon colours obtained?

There are 3 key factors in dictating the colour of a neon sign.

- The gas used. Neon gas creates the colour red whereas Argon gas is used to create most other colours.

- The colour of the glass. Some colours, such as Yellow, can only be created using yellow-coloured glass. The advantage of this is that the neon sign remains coloured when turned off but a downside is that the glass is slightly more expensive.

- Powdered glass. Most ‘neon’ glass is White when turned off. The reason for this is a fluorescent powder has been applied to the inside of the glass tube. When a current is passed through the glass and the Neon or Argon gas starts to emit light, the colour of the neon tube is created by the powdered applied to the inside. This is the way in which most colours are created including Turquoise, Pink, White and Green neon.

How long does to take to make a neon sign?

All of our neon signs are made by hand in the UK. The process can take anywhere from 1-3 days for the actual work to be undertaken.

How do I commission a neon sign?

The first step is to create a design. At this stage we don’t need to get into too much detail at all. You may already have an idea for the design – perhaps a phrase or shape – that you’d like as a neon light, or alternatively we can propose one. As well as the design you’d like, the only things we need to know at this stage are the colour(s) you’d like, the space limitation that we need to work within, and an idea of how you’d like the neon mounted (more of that below).

We will then propose a design to see what you think. We’ll also give an indication of costs. At this stage we’ll also have a chat about where you’d like the neon mounting. Perhaps you’d like your neon light directly mounting to the wall or you’d like it in a protective box.

Once the design and mount have been agreed then we start production and keep you up to speed with timescales for delivery!

How are neon signs mounted?

There are various ways to mounted neon signs. The neon glass can be mounted directly to your wall, in which case you’ll need a specialist installer to undertake the work which we can help with. Alternatively, we can mount your neon so it comes delivered as a final light, ready to put up and plug in. In those instances, the most common ways we mount the neon are

- Trough-Style Lettering. A style often used for text, built-up trough style lettering is produced from wither Steel or Aluminium. The metalwork is often painted and then the neon is fittied into the trough which then brings the lettering to life.

- Acrylic panel. The panel onto which the neon is mounted can be a simple shape (eg square or circular) or cut to the rough outline shape of your design. We can use clear or coloured acrylic. With this method the ‘workings’, ie the connecting cables and transformer, are visible so it has more of an industrial look.

- Powdercoated panel. We produce a steel or aluminium panel which would only be approx.. 80mm deep, We then powdercoat (professionally paint) the box any standard RAL colour. The neon is mounted to the surface of the box and the transformer and most cables are hidden within the box. The main power supply cable can exit the rear of the box if it is being hard-wired or the power cable can exit from any side of the box if required. This is arguably the most sleek way to mount neon.

- Vinyl-coated panel. The panel can be either acrylic or metal, and over this we fix a printed acrylic. This is an effective solution for when the design, often a logo, is complex, or if we want a certain effect behind the neon such as a glitter as was required for the Children In Need light we produced for the BBC.

- Directly to a wall. More information on this is below.

- Acrylic box. Mounting neon within an acrylic box will give protection to the neon. We add holes so you can fix the box to a wall or surface and also put ventilation holes on the top edge of the box. As with the panel method, the working s will be visible.

Clockwise from top-left: (i) mounted within red powdercoated trough lettering, (ii) mounted to clear acrylic panel which is then fixed to wall, (iii) mounted to white powdercoated steel panel, (iv) mounted to glitter effect vinyl-covered acrylic panel, (v) mounted directly to wall and (vi) mounted within self-standing clear exhibition-grade acrylic box.

How do I get a neon sign installed directly to my wall?

If you would like the neon mounted directly to your wall then we’ll organize for the specialist installer to contact you prior to the install. They will discuss where exactly the neon will be located and also discuss the power supply and how you want to turn the neon on and off. They may need to come to put specialist cable sin place prior to the neon being installed or they may be able to do it all on the same day. They will also discuss where the transformer will be located. The final stage will be when they bring the mounting template and neon to your location during which they will fix the neon supports to your wall, clip the glass onto the supports, connect the glass together and then test the neon is working.

Hot Pink neon mounted directly to brick wall. Client: Soho House

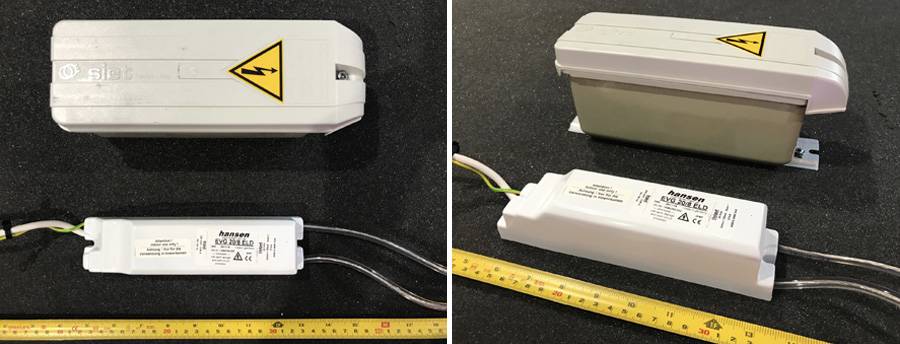

What do neon transformers look like and how do you choose which one to use?

All neon transformers operate at high voltage, typically 1,000V to 10,000V and as such we only use European CE-marked transformers, usually from Germany or Italy. We don’t use any neon transformers that have been made in the Far East.

TOP – 8kV 25mA Siet transformer; BOTTOM – 8kV 20mA Hansen transformer

There are two different type of neon transformers. Electronic and resin block

1. Electronic neon transformers, typically the Hansen brand, are relatively small and the voltage self-regulates up to the maximum operating voltage of the transformer. They’re available in wither Black or White colour and some of these are dimmable. The disadvantage is that the output HT leads can’t be lengthened meaning the transformer needs to be located 1-1.5m from the neon sign tubes. They’re typically for indoor use only.

2. Resin block, typically Siet transformers, are much larger than electronic transformers and much heavier. They can buzz slightly and can get warm. They therefore need to be located in a well-ventilated area. The advantage of these transformers is that they can be located far further away from the neon glass and they’re outdoor rated so can be used either indoors or outdoors.

What do Neon Signs look like when turned off?

It very much depends on the glass used. In general however, it’s fair to say that most lights look white when turned off, some still remain coloured when not illuminated and some may appear like clear glass.

When the light is turned off, Hot-Pink and Superblue are White, ‘Clear Red’ is clear glass and Bromo Blue and Ruby Red are Blue/Red.

What are the limitations of real neon signs?

The main feedback we hear relates to the fragility of neon. It’s made from glass and is therefore fragile. Depending on your application, this may not be suitable if the neon is being located in areas within reach of customers such as Hotels or Nightclubs. It would be fine for Retail use if out of reach. The other consideration is that the Neon transformers operate at high voltage and as such, you may need an externally-located Fireman’s Switch., This limitation means that commercial customers often ask us for Neon Ultra® or Neon SuperFlex instead of real neon.

Are Neon Signs sustainable and eco-friendly?

Neon signs are generally considered to be an eco-friendly and sustainable luminaire. They are manufactured from glass and inert gas (either neon or argon). They are designed to last for decades and are not considered a ‘disposable product’. The efficiency of a neon illumination depends no the colour, but can be considered to be similar to that of fluorescent lamps. Neon light efficiency can be up to 60 lumens per Watt. In comparison, fluorescent lamps emit 50-100 lumens per Watt, whilst traditional incandescent house bulbs produce only 10-20 lumens of light per Watt. All of a neon sign’s components are recyclable, but in the event of a failure of a specific component, it’s standard practice to repair or replace only specific items without having to dispose of the sign as a whole.

What’s the difference between LED neon and neon signs?

Although they both have the name ‘neon’ in them, LED ‘neon’ isn’t neon at all. You may hear various terms such as Faux Neon, LED Neon, Fake Neon or Neon Flex, but they all mean the same thing – a lighting product that is designed to mimic the effect of real neon but isn’t neon at all. Our products in this range are Neon Ultra® and Neon SuperFlex.

A key point to note is that some companies only sell replica LED ‘neon’ but they just refer to it as neon. It’s important to understand where your product is actually being manufactured as this will give an idea as to it’s quality and safety.

Replica LED neon signs employ low-voltage (typically 12V or 24V) LEDs which are inset into a ribbon or acrylic, and follow the overall design shape of the design in question.

Our LED neon products are now equally popular as our real neon, and the trend for these products is growing. The fact that they’re considerably more robust than real neon is a key reason for this, and as such, we’re often asked to supply replica faux neon to customers such as Bars, Hotels and Restaurants.

Is Neon Ultra the same as Neon SuperFlex?

Apart from the fact they’re both designed to be replica products, they’re produced in a very different way. SuperFlex lights are made from LED flex which we use to follow the outline of a design. We can bend it into fairly tihgt curves and cut it into sections which are soldered together. The flex has to be held in place to maintain the shape of the design, so we do this by cutting a channel into clear acrylic which then holds it in place.

Neon SuperFlex Dinosaurs for Coach’s flagship Christmas windows on Oxford Street, London

Neon Ultra is produce from a thick sheet of opal acrylic. The design is lasercut from the panel and a channel is cut into the back into which LED illumination is inserted. The face is then beveled into an opal shape to mimic tglass and vinyl is applied to the sides to hide the ‘workings’. he end result with both products is a neon replica light, but the products are very different.

Neon Ultra® light for event in Ibiza

LED neon v. real neon? Which is better?

It’s very much a matter of ‘horses for courses’. Going from what our extensive list of customers ask us for, faux LED neon tends to be more popular when (i) the light is for commercial use the customer’s has specified no high voltage or fragile illuminations, (ii) the light will be within reach of the public, (iii) the decorative light is being moved around a lot, (iv) when animation is required or (iv) cost dictates that LED neon is preferable

Example of these could be public Events, Live Music Gigs or Football Stadia, all of which we’ve produced faux neon lights for over the past years.

Neon Ultra® (Faux LED Neon) lights at a live Dua Lipa gig, Tottenham Hotspur Stadium’s ‘Smashed Olive’ and directional wayfinding at the 02 Arena.

Can LED Neon be animated?

Yes, this is a huge advantage of faux neon. Flex can only dim or flash but when an RGB lightsource is inserted into Neon Ultra® then it opens the door to a huge range of animation options, from simple flashing/dimming to fully animated colour changing through a DMX unit. These types of lights can be supplied with a pre-programmed DMX unit or can be controlled through your own lighting desk.

Neon Ultra® light at the Barclaycard Arena – supplied with a pre-programmed DMX controller to make it mostly pink but intermittently flicker to a vivid Blue.

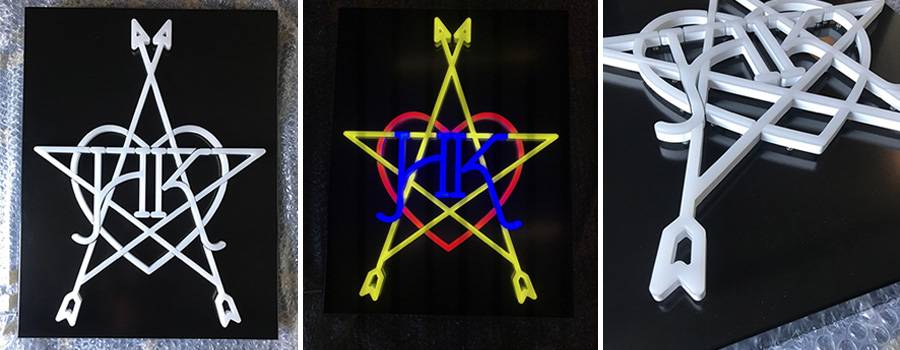

My logo is quite complex – can I still get it made as a neon light?

Yes you can. The 2 options are:

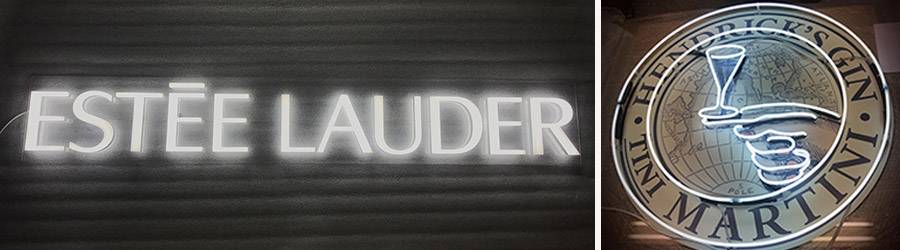

- With Ultra® being cut from sheet acrylic, we’re able to bring more complex designs to life with this product. The key advantage here is that we’re able to produce fonts which have thicks and thins, so long as the narrowest point is still wide enough for us to insert the LED tape.

- If we make it from real neon then we can use vinyl to bring the complex elements of the design to life. We would then overly neon over the top of this to bring certain elements of the design to life in light.

ESTEE LAUDER produced from Ultra, enabling the production of thick and thin elements of the logo; White neon laid over a complex Hendricks design which was printed onto vinyl and stuck into a clear acrylic box.

Where’s the best place to buy neon?

Someone relatively local is always a good place to start. We hear a lot of stories about people who have purchase a real neon or LED neon sign from overseas, and if there is a problem then it can be very hard to get it fixed. All of our lights are made in Britain, and as such we can offer a complete and reliable service.