How do lightboxes work?

Whether for artistic and scientific endeavours, lightboxes play a pivotal role in providing a uniform and controlled source of illumination. From tracing intricate designs to examining X-ray films, these devices have become indispensable tools. This article delves into the workings of lightboxes, shedding light on their components, functionality, and diverse applications.

Overview of Lightboxes

A lightbox, also known as a light table, illuminated tracing board or internally illuminated box, is a flat surface with built-in lighting that emits uniform illumination from beneath. The design typically consists of a translucent or transparent panel, such as glass or acrylic, supported by a sturdy frame. These devices are available in various sizes, catering to the needs of different fields, ranging from art and design to medical diagnostics and signage (our speciality obviously).

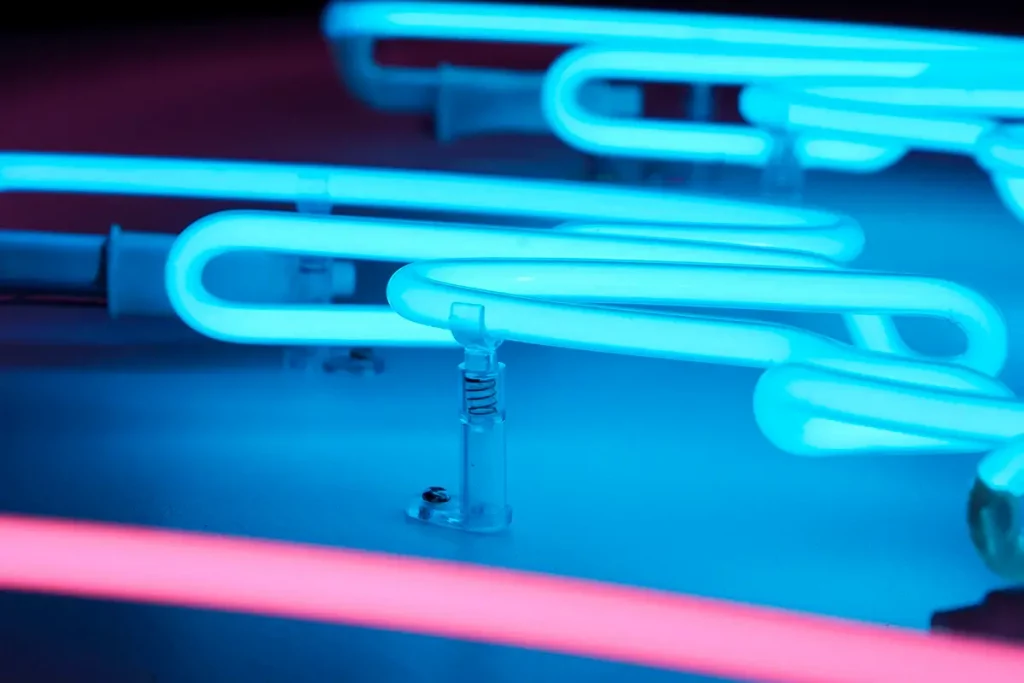

The Light Source

At the core of every lightbox is its light source, responsible for generating the even illumination required for their operation. Traditionally, fluorescent tubes were employed as the primary light source, but modern lightboxes utilise LED (Light-Emitting Diode) technology. LEDs offer several advantages, including energy efficiency, longevity, and the ability to produce a broader range of colours. They’re also far more robust which is particular advantage for our clients when employed as lightbox signage solutions.

Construction and Components

The construction of a lightbox involves several key components. The main body comprises a durable frame, often made of steel, aluminium or plastic, providing stability and support. On top of this frame rests the translucent or transparent panel, ensuring optimal light transmission while maintaining a smooth working surface. The light source, typically an array of LEDs, is positioned beneath the panel, evenly illuminating the entire surface. The shallower the depth of the lightbox, the more LED modules are required to give an even distribution of illumination. Conversely, if the lightbox is deep then fewer LED modules are required for the lightbox as the emitted light has greater distance to dissipate before it reaches the translucent panel.

Extruded Lightboxes

Aluminium lightboxes are often manufactured using an extrusion process, specifically aluminium extrusion. Extrusion is a manufacturing method that involves shaping or forming aluminium by forcing it through a shaped opening or die under high pressure. Here’s a general overview of how aluminium lightboxes are extruded:

Design and Die Creation: The extrusion process begins with the design of the lightbox profile. The desired shape and dimensions of the lightbox frame, including the front and back panels, are determined. Based on this design, a custom die is created. The die is typically made of hardened steel and has a profile that matches the desired shape of the lightbox frame.

Billet Heating: Aluminium billets, which are long cylindrical bars of aluminium, are heated to a specific temperature. The temperature depends on the type and alloy of aluminium being used. Heating the billets softens the aluminium, making it more malleable for the extrusion process.

Extrusion Process: The heated aluminium billet is loaded into a hydraulic press or extrusion machine. The billet is then pushed through the die using a ram or screw mechanism. The pressure applied by the machine forces the softened aluminium through the shaped opening of the die. As the aluminium passes through the die, it takes on the shape and dimensions of the lightbox profile.

Cooling and Straightening: Once the aluminium has been extruded through the die, it undergoes a cooling process. This can involve air or water cooling methods to rapidly cool down the extruded profile. After cooling, the extruded aluminium profile may undergo a straightening process to ensure it is perfectly aligned and free from any warping or twisting.

Finishing and Assembly: The extruded aluminium profile is typically cut into appropriate lengths to form the frame of the lightbox. Additional machining processes, such as drilling or tapping, may be performed to create openings for components like LED lights or mounting brackets. The extruded frame is then finished, which can involve processes like anodising, powder coating, or painting to enhance its appearance and provide protection against corrosion.

Panel and Component Installation: Once the frame is ready, the translucent or transparent panels, such as glass or acrylic, are installed. These panels are often secured within the frame using clips, brackets, or adhesive methods. Other components, such as LED lighting modules, wiring, and power supplies, may also be installed within the lightbox frame.

Quality Control and Inspection: After assembly, the finished aluminium lightboxes undergo thorough quality control inspections. This ensures that the final products meet the required specifications, including dimensional accuracy, structural integrity, and proper functioning of electrical components.

By utilising the extrusion process, manufacturers can efficiently produce aluminium lightboxes with consistent shapes, dimensions, and quality. The versatility of aluminium extrusion allows for customisation, enabling the creation of various lightbox designs to meet specific customer requirements.

Functionality and Controls

Lightboxes can be designed to offer adjustable brightness levels, enabling users to customise the intensity of illumination according to their specific requirements. To achieve this, modern lightboxes incorporate control mechanisms such as buttons, switches, or touch-sensitive panels. These controls facilitate easy adjustment of brightness and, in some advanced models, colour temperature for enhanced versatility. This is particularly important in the signage industry as the brightness of a lightbox will need to be set at a very different level for a sign in a retail shop window in sunshine compared with the exact same lightbox which is located in a darker fitting room area for example.

Lightboxes Applications

Lightboxes find applications across a wide array of fields. In the artistic realm, they serve as invaluable tools for tracing, allowing artists to transfer sketches, patterns, or designs onto different mediums with precision. In the world of graphic design, lightboxes aid in the creation of intricate and detailed artwork. Additionally, lightboxes have become indispensable in medical imaging, where they are used to examine X-ray films, transparencies, or negatives. In our world, they are used as signage for various industries. Sports stadium signage requirements may lead to them being employed in a wayfinding signage function, whereas the marketing and advertising world are inclined to commission brand and logo lightboxes for brand activation campaigns.

Lightbox therapy is another vital application. Using a very different method to that generally described so far, but still under the general group of lightboxes, lightboxes are employed by the NHS and other health professionals to aid with SAD (Seasonal Affectiveness Disorder). In essence, they’re designed to mimic daylight, thus encouraging the brain to reduce production of melotonin (makes you sleepy) and increase the production of serotonin (which affects your mood).

Advancements and Innovations

The continuous evolution of lightbox technology has led to several advancements and innovations. Portable and battery-operated lightboxes have become increasingly popular, providing greater flexibility and convenience for artists on the go. Additionally, some lightboxes now incorporate features like adjustable colour temperature, USB connectivity, and dimmable lighting to cater to the specific needs of professionals.

Lightboxes have revolutionised various industries, providing a consistent and controlled source of illumination for a myriad of applications. Whether used by artists seeking precision or medical professionals analysing diagnostic images, these devices continue to play an essential role in enhancing productivity and efficiency. As technology advances, we can expect lightboxes to evolve further, empowering individuals across diverse fields with the gift of light and clarity.